SAF Feasibility Report

3rd September 2025

Ministry of Civil Aviation, in partnership with the International Civil Aviation Organization (ICAO) and with support from the European Union has officially released the Sustainable Aviation Fuel (SAF) Feasibility Study for India

Undertaken under the ICAO ACT-SAF Programme, the feasibility study assesses the potential for producing and utilizing drop-in Sustainable Aviation Fuel (SAF) in India. It evaluates domestic feedstock availability, viable production pathways, infrastructure and policy readiness and the enabling conditions needed to establish a robust domestic SAF market. Drawing upon international best practices and tailoring them to India’s socio-economic and environmental context, the report provides a roadmap for sustainable fuel adoption

SAF is a practical and immediate solution to decarbonize the aviation sector, with the potential to cut lifecycle CO2 emissions by up to 80% compared to conventional fuel. With over 750 million metric tonnes of available biomass and nearly 230 million metric tonnes of surplus agricultural residue, India has the capacity not only to meet its own SAF demand but also to emerge as a global leader and exporter

We present Summary of this 139-page report

- The Indian government and other stakeholders are committed to the development of a domestic SAF industry. The government has set targets of a 1% SAF blend by 2027, 2% by 2028, and 5% by 2030

- Numerous stakeholders are actively involved in the development of a SAF sector, including petroleum refiners, SAF technology developers, feedstock suppliers, airlines, original equipment manufacturers, etc.

- The first volumes of SAF are expected to be produced in the latter half of 2025 through coprocessing of UCO in an existing refinery

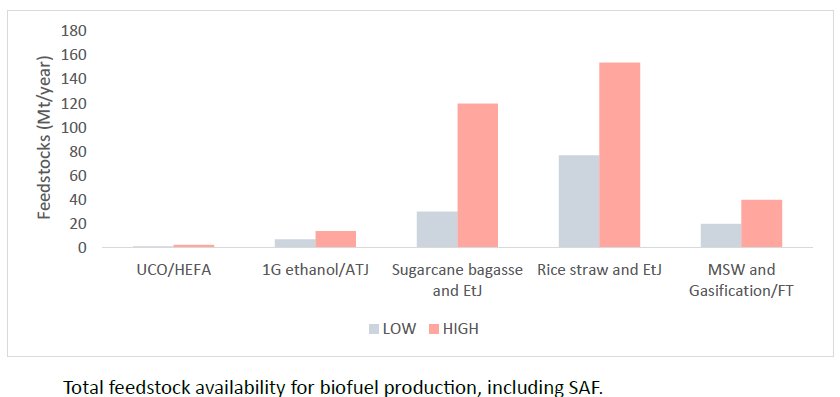

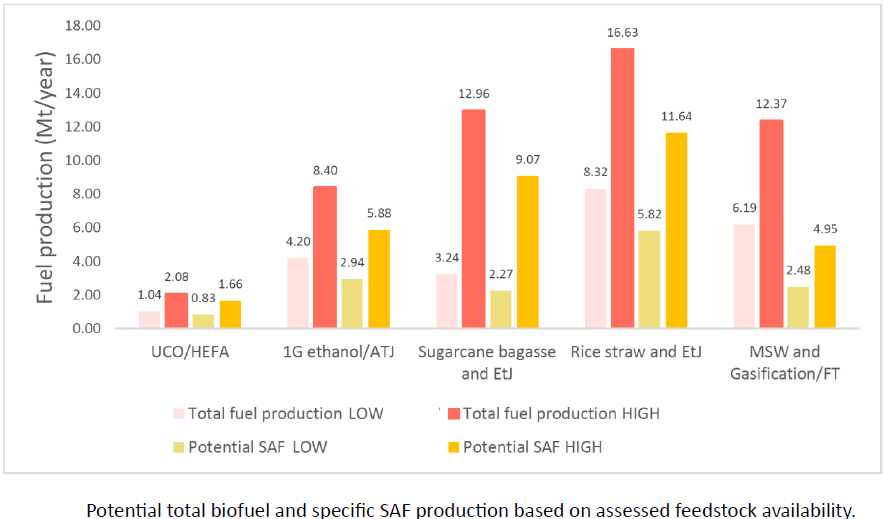

- This study carried out a comprehensive assessment of feedstocks available in India and potential SAF technologies that could utilize them. India has vast resources of bio-based feedstocks that could potentially be used to produce SAF, with sugarcane bagasse, rice straw, and municipal solid waste forming the bulk of the biogenic feedstocks

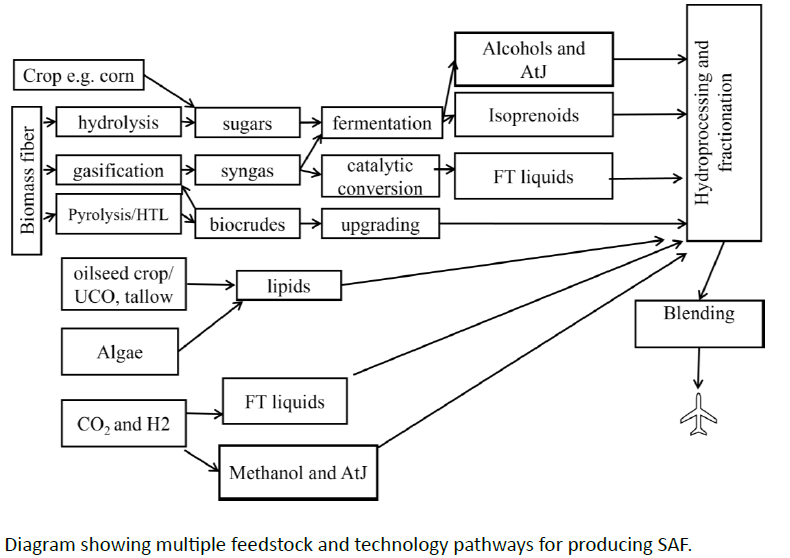

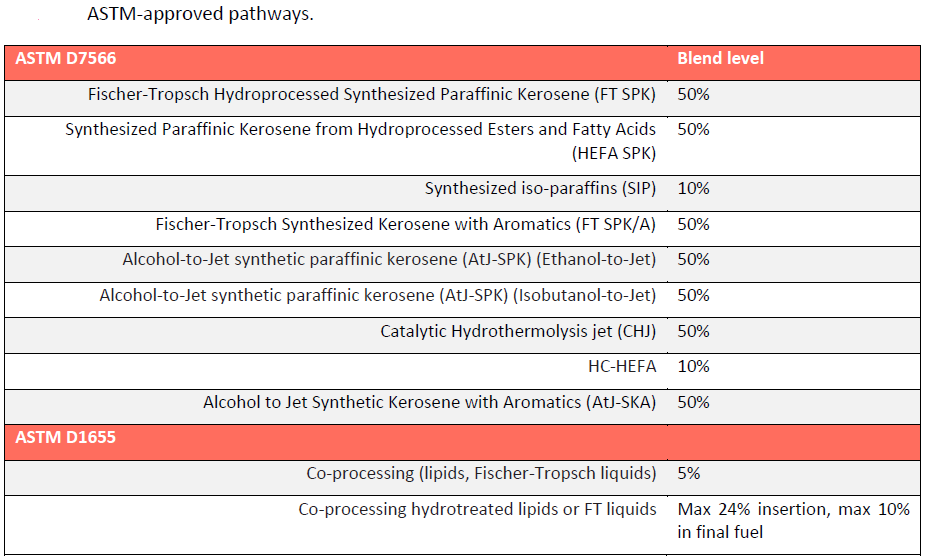

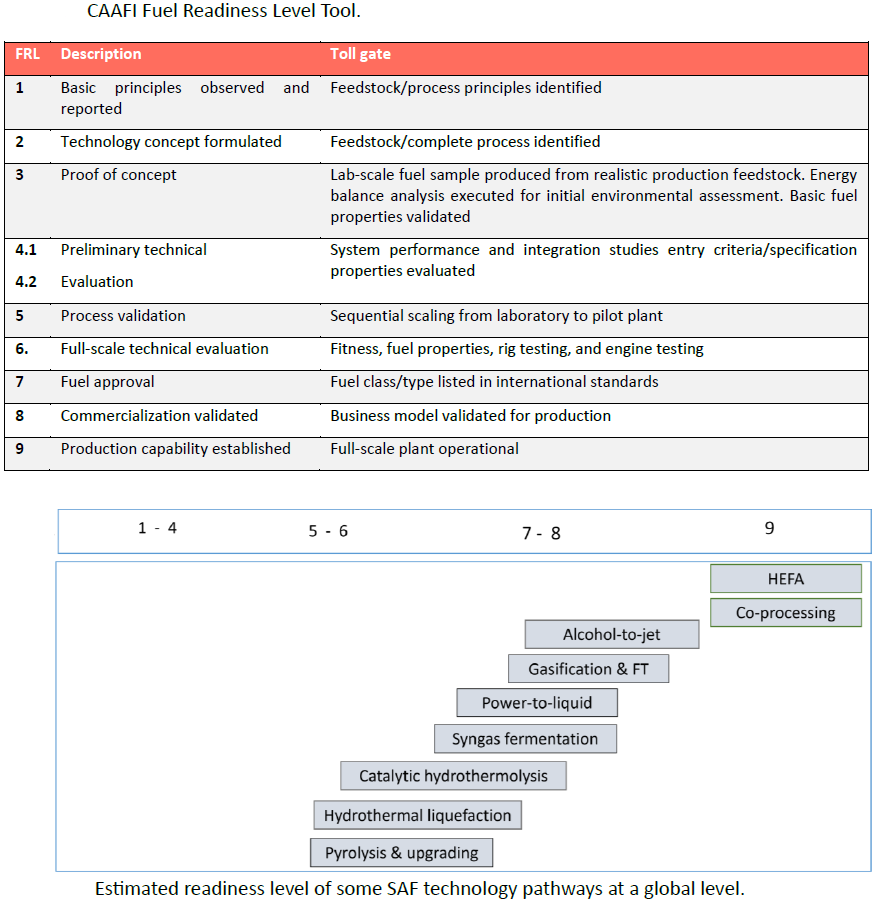

- The SAF technologies that can use these feedstocks are still undergoing commercialization, including the production of 2G2 ethanol from bagasse and rice straw and the alcohol-to-jet process

- For municipal solid waste (MSW), the main technology route that has been pursued is gasification with Fischer-Tropsch synthesis

- However, commercialization has been very challenging, with many technical obstacles remaining due to the challenging nature and complexity of the feedstock

- While these feedstocks can supply very significant volumes of SAF, the critical challenge is to reach commercial scale with first-of-a-kind facilities at a global level

- The production of SAF through the alcohol-to-jet (AtJ) process presents the largest opportunity for India as a route to SAF production. There are many different sources of ethanol based on different feedstocks and process routes, and the ethanol intermediate is chemically identical. The ethanol can be transported and aggregated for large-scale AtJ facilities, regardless of the source of ethanol

- 2G or second generation ethanol, also called cellulosic ethanol or advanced ethanol, is based on lignocellulose feedstocks such as rice straw or based on processes such as waste gas fermentation. The report highlights that to utilize this feedstock for SAF production, hundreds of such 2G ethanol facilities will be required. Sugarcane bagasse is an “easier” feedstock for 2G ethanol production and has been successfully demonstrated in Brazil by the company Raizen. The bagasse supply chain and feedstock characteristics have fewer challenges than rice straw, and this feedstock should be a primary target for 2G ethanol to support SAF production.

- Due to the challenges and expected slow pace of scale-up of 2G ethanol from residues, establishing alcohol-to-jet plants based only on 2G ethanol will result in avoidable delays in SAF production. It is therefore recommended that 1G ethanol be used for establishing commercial-scale AtJ facilities until 2G ethanol becomes more available. Sugarcane ethanol, in particular, can deliver very low carbon-intensive SAF, but policy considerations with respect to food security and ethanol blending in gasoline should be addressed. From a fuel blending perspective, broader climate goals should be considered, as the aviation sector has very limited options (mainly SAF), while road transportation has many other options

- Another source of 2G ethanol that is actively pursued by technology providers, such as Lanzatech, is the fermentation of waste gases (from industrial point sources) and from syngas (gasification of feedstocks such as MSW). Lanzatech’s gas fermentation facility at IOCL will have a capacity of 33 kt/year. This has very significant potential due to the substantial emissions from sources such as steelmaking, cement production, refinery off-gases, etc.

- The HEFA process using oils, fats, and greases is the only fully commercial technology for SAF production, both through stand-alone facilities and co-processing in existing conventional refineries (HEFA: Hydroprocessed Esters and Fatty Acids)

- However, relatively low volumes of waste oils are available in India. As India is a net importer of vegetable oils, these feedstocks are not considered available for SAF production

- Although the availability of used cooking oil (UCO) can potentially be increased, this will depend on improved collection, additional pre-treatment facilities, and prevention of unsafe reuse of UCO

- Even if all the UCO can be collected and utilized, it can only supply limited volumes of SAF compared to other feedstocks

- However, in the short term, SAF production in India will be based on UCO. In the medium to long term, expansion of inedible oil cultivation could increase the supply of HEFA feedstocks

- Although this study is concerned with SAF production, other fuel products, such as renewable diesel and renewable naphtha (for gasoline), are also produced

- At a low estimate, more than 14 million tonnes (Mt) per year of SAF can be produced from these feedstocks, with a high estimate of over 33 Mt/year. This does not include the potential SAF from waste gas fermentation or power-to-liquids based on point sources

- The potential low estimate of SAF volumes that can be produced in India is more than sufficient to supply up to 70% SAF blends into all jet fuel used in India (based on jet fuel forecasts to 2050), with additional SAF available for export

- The SAF industry faces many well-documented challenges, including lack of SAF availability, slow commercialization of technologies, high production costs, and others

- At the same time, ICA`s LTAG analysis has shown that the majority of emissions reductions in the sector must come from SAF, with no other option for medium- and long-haul flights for decades to come (LTAG: Long-Term Aspirational Goal)

- The production of hundreds of billions of litres of SAF will be essential for meeting the industry’s net zero target by 2050. However, SAF production volumes are still less than 1% of total jet fuel demand, and commercialising new technologies and scaling up are critical, globally and in India

- There is a consensus that policies supporting the production and consumption of SAF will be critical for the industry

- Policies in Brazil, the USA, the EU, and the UK for SAF have been relatively comprehensive and can provide insights for India to develop domestic policies to facilitate SAF production and consumption

- India has many existing policies for supporting biofuel production and blending and supporting the development of nascent industries through financing

- These policy frameworks can serve as a scaffold for building SAF-specific policies

- Extending existing regulations to SAF development but modifying them to take into account SAF-specific considerations could integrate the overall biofuel sector while targeting long-term climate goals

- The National Biofuels Policy can incorporate and integrate SAF, while existing institutions such as IREDA, NABARD, SIDBI, and other PSBs (public sector banks) could be leveraged for the development of SAF production facilities

- Support for feedstock development and improvement of feedstock-related challenges could be incorporated into an existing body such as ICAR (Indian Council of Agricultural Research). Furthermore, funding to develop technologies and support near-commercial projects could be leveraged through OIDB and CSIR

- Above all, the financing of SAF development, production, and consumption is a critical challenge. A basket of policies and pathways for achieving this is recommended, including grants and loan guarantees for the construction of first-of-a-kind facilities and other financial support mechanisms such as tax credits and incentives

- Creating a long-term structural demand as an integral part of a long-term vision and strategy to 2050 will provide certainty and serve to derisk investment while also creating a level playing field between airlines

- Overall, the development of a long-term vision for a SAF sector in India will be critical to focus efforts from stakeholders and government. Therefore, the establishment of a SAF Council (similar to, as an illustrative example, the Jet Zero Council in the UK) is recommended with high-level representatives from government departments and CEOs from relevant stakeholders with decision-making power to ensure fast and effective development of a vision and strategy for the future of a domestic SAF sector

- Urgent action is needed to establish a policy framework for SAF development in India. Multiple companies are engaged in SAF development and commercialization in India but are faced with high construction costs and high production costs. The right mixture of policies can facilitate the rapid development of a SAF industry in India

- India needs a strong sustainability framework for all biofuels that should be integrated with the globally recognized sustainability requirements for SAF established under the ICAO CORSIA standard to ensure maximum climate benefits