Conversion Factors: Petroleum Products

Source: United Nations Statistics Division (UNSD), energy conversion conventions.

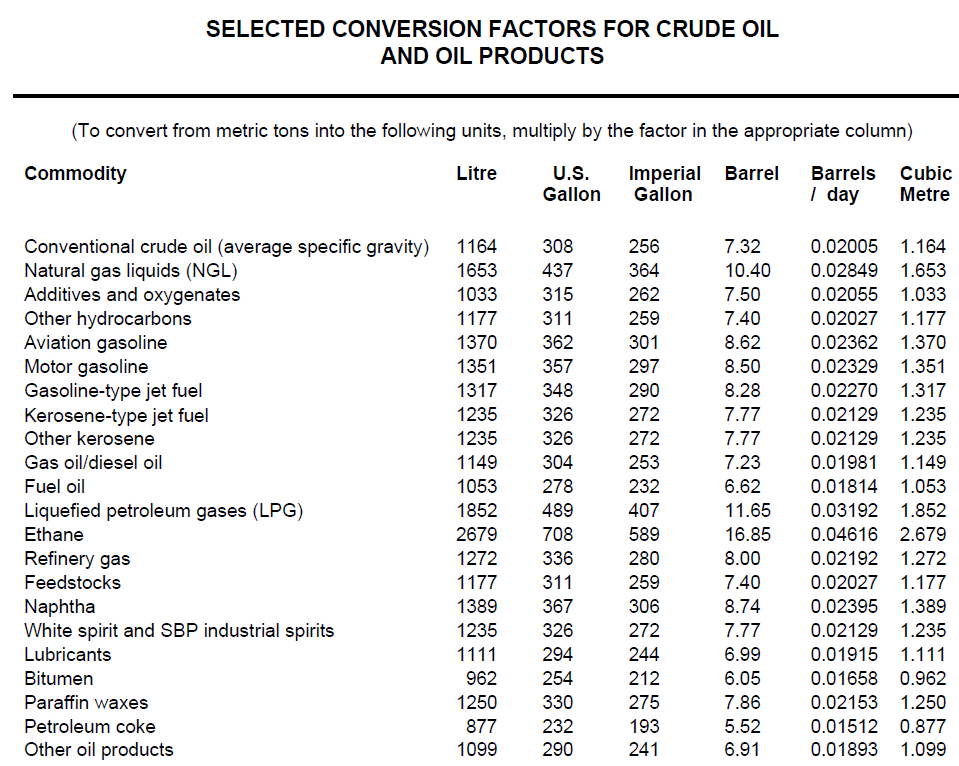

Petroleum products are reported across mass, volume, and flow units depending on the agency and context. The table below, adapted from UNSD conventions, captures standard conversion factors used to translate metric tonnes of major petroleum products into litres, barrels, barrels per day, and cubic metres.

Unlike natural gas, petroleum products exhibit wide variation in density. As a result, the number of barrels represented by one metric tonne differs significantly across products.

Two extreme examples from the table illustrate this clearly:

• Liquefied Petroleum Gas (LPG): ~11.65 barrels per tonne

• Bitumen: ~6.05 barrels per tonne

This wide spread reflects differences in product density and explains why a single “ton-to-barrel” conversion factor does not exist across petroleum products.

Refineries across the world follow different conventions when reporting both crude processing capacity and product-wise output.

For example, a refinery may describe its crude throughput as 10 million tonnes per annum (MMTPA), while another may refer to the same capacity as approximately 200,000 barrels per day (200 kbpd).

Similarly, gasoline production may be reported either in mass terms (tonnes) or volume terms (barrels per day).

If gasoline production is reported as 2 million tonnes per year, referring to the UNSD table:

Gasoline conversion factor ≈ 8.5 barrels per tonne

This corresponds to:

2,000,000 × 8.5 / 365 ≈ 46,575 barrels per day.

Gasoline’s barrels-per-tonne ratio is significantly higher than that of crude oil because gasoline is much lighter than crude.

As a result, a refinery producing gasoline with a 20% yield on a mass basis would report a higher yield on a volume basis. In this example:

46,575 kbpd / 200,000 kbpd ≈ 23.3%

This divergence between mass and volume yields is a direct consequence of density differences and is routinely encountered when reconciling refinery output data across different reporting conventions.